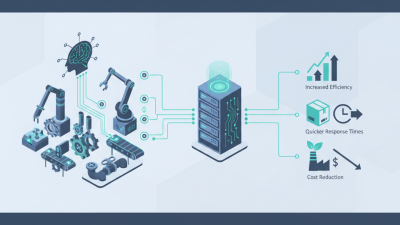

In today's rapidly evolving industrial landscape, the importance of controls and automation cannot be overstated. A recent report from McKinsey highlights that companies implementing advanced automation can boost productivity by up to 40%. This remarkable efficiency is not just about reducing human labor; it’s about optimizing operations, enhancing quality, and driving innovation. As industries face mounting pressure to improve performance, embracing controls and automation is no longer optional.

Moreover, a study by Gartner found that over 60% of organizations that adopted smart automation saw reduced operational costs. These data points illustrate the profound impact of controls and automation on various sectors. Yet, challenges remain. Many companies struggle with integrating these technologies effectively. Even with the best tools, inefficiencies can persist if proper strategies are not in place. Thus, understanding how to navigate these complexities is crucial for achieving optimal outcomes.

In light of these insights, exploring practical tips for leveraging controls and automation is essential. As organizations strive for excellence, reflection on existing practices provides an opportunity to enhance systems further. Embracing innovation while acknowledging areas for improvement is a vital step toward sustainable efficiency.

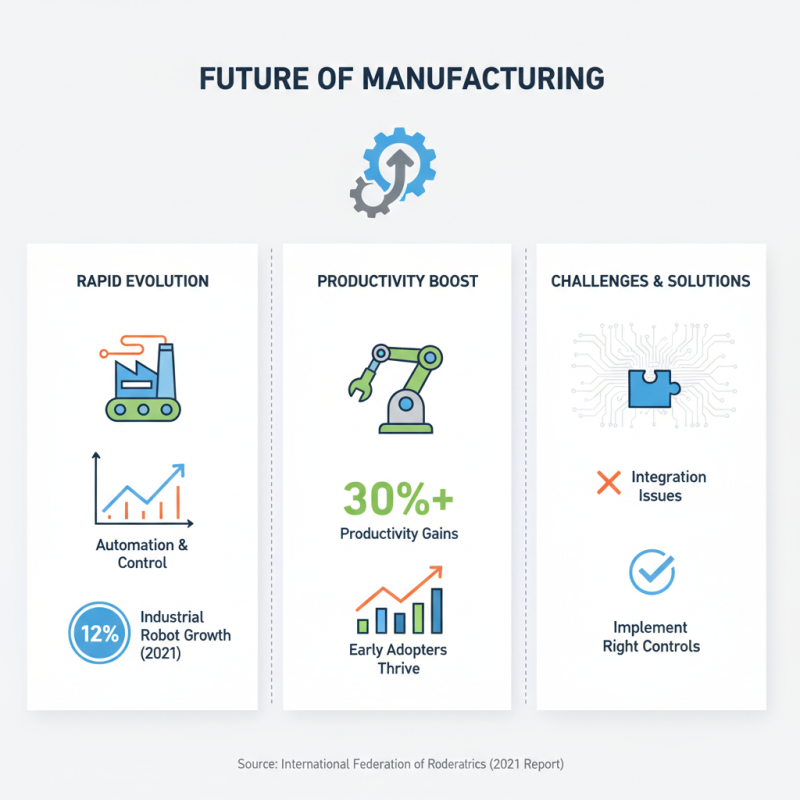

Manufacturing processes are evolving rapidly. Implementing the right controls can significantly enhance automation. A report from the International Federation of Robotics indicates that industrial robot installations grew by 12% in 2021. Companies that embrace these technologies often see productivity gains of over 30%. Yet, many still struggle with integration issues.

One main aspect is the need for real-time data monitoring. Only 40% of manufacturers utilize advanced analytics effectively, according to a McKinsey study. This lack leads to inefficiencies. It’s crucial to invest in systems that can analyze data on the fly. Simple dashboards can provide vital insights but are often not optimized. Another critical factor is workforce training. A report from Deloitte found that about 40% of employees feel inadequately prepared for new technologies. This gap can hinder progress.

Despite advancements, challenges remain. Cybersecurity is a significant concern as processes become more interconnected. Manufacturers must prioritize secure systems. Moreover, there’s a perception that automation leads to job losses, which can create resistance among staff. Addressing these fears through clear communication is essential for successful implementation. Balancing technology with human skills is the key to realizing automation's full potential.

Measuring automation efficiency requires clear metrics. Key metrics can reveal how well your systems perform. Focus on cycle time, error rates, and throughput. These metrics provide insight into the strengths and weaknesses of your processes.

Tip one: Regularly review data trends. Identify patterns that indicate when efficiency dips. Sometimes, problems arise from overlooked factors. Encourage team discussions to address these issues promptly.

Tip two: Use benchmarking. Compare your metrics against industry standards. This helps you understand where you stand. An ongoing assessment can highlight areas for improvement. Reflection on past performance informs future strategies.

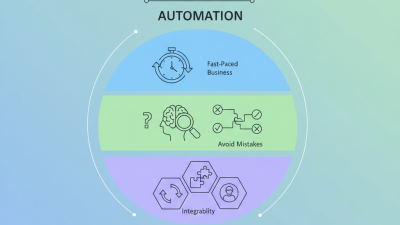

Automation is not about perfection. It involves constant refinement. Set realistic goals. Embrace the notion that some days will be less efficient than others. Analyze why this happens and adjust accordingly. Flexibility is key in optimizing automation systems.

This chart illustrates the efficiency percentages of different automated processes. By visualizing this data, organizations can identify which processes are performing optimally and which may require further optimization efforts.

Effective data management is crucial for any automation system. Accurate data collection leads to better decision-making. Ensuring data integrity is a constant challenge. Regular audits are essential. They help identify discrepancies and maintain quality. Setting clear protocols for data entry can minimize errors. Training staff in these protocols is equally important.

Automation systems thrive on well-structured data. Inconsistent data can lead to system failures. Streamlining data workflows helps to reduce redundancy. Simplifying the data management process can improve responsiveness. However, not every team member may adapt easily. Some may struggle with new tools. Continuous support and guidance are vital for success.

Implementing a feedback loop is beneficial. This allows teams to relay issues with data management. Adapting based on feedback improves overall efficiency. It also fosters a culture of continuous improvement. Problems will arise, and learning from them is part of the journey. Consideration of different perspectives can enhance solutions. Embrace imperfections; they often lead to breakthroughs.

Integrating IoT technologies can revolutionize industrial automation. Many industries still lag in utilizing these advancements. Sensors and smart devices can collect real-time data. This allows companies to monitor operations closely. With this information, businesses can make informed decisions quickly. However, not all organizations implement these systems effectively.

Data overload is a common issue. Companies need to filter what’s important. Some struggle to integrate new systems with existing structures. This can lead to confusion and inefficiency. Employee training is also essential. Without proper knowledge, staff may resist adopting new tools.

Investing in IoT technologies is a lengthy process. Unexpected challenges can arise, such as cybersecurity risks. Yet, the potential rewards are substantial. Increased productivity and reduced operational costs often lead to better profits. Those willing to innovate will likely find success.

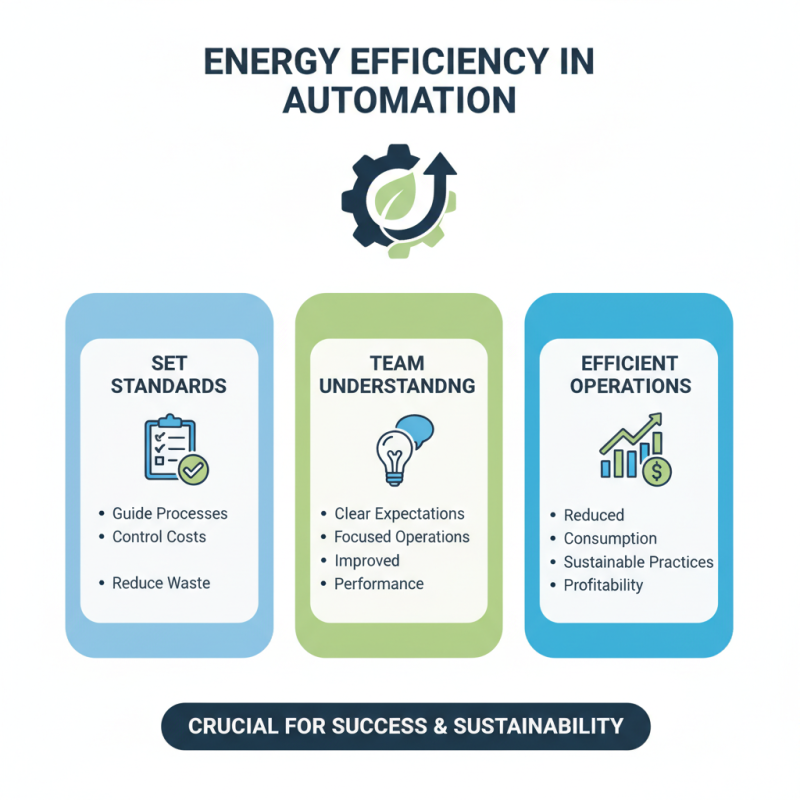

Energy efficiency is crucial in automation. Companies must set clear standards to guide their processes. These standards help in controlling costs and reducing waste. When teams understand what is expected, they can focus on efficient operations.

Implementing energy-efficient technologies can feel overwhelming. Many businesses struggle with identifying the right solutions. Common mistakes include neglecting routine maintenance and ignoring employee training. These oversights can lead to increased energy consumption and lost opportunities. Staff engagement is vital. Everyone should be on board with energy-saving practices to maximize ROI.

Tracking energy use is also essential. Organizations often fail to monitor their consumption accurately. Real-time data allows for quick adjustments. It can reveal unexpected inefficiencies. These insights drive continuous improvement and may lead to substantial savings. Savvy operations routinely review their performance against energy standards to stay competitive.