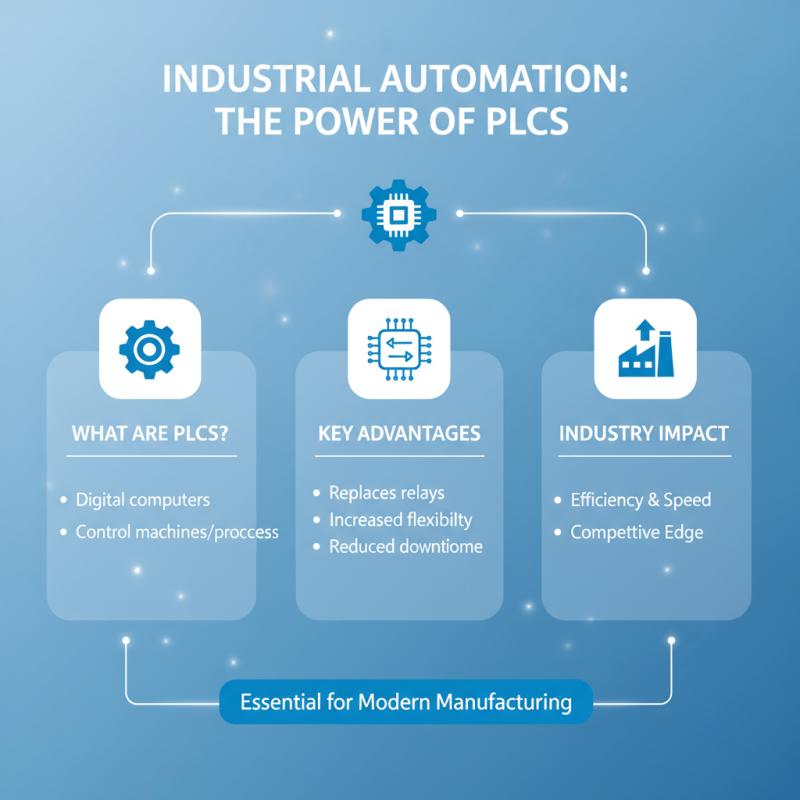

PLC engineering stands as a cornerstone in modern industrial automation. This field focuses on the design and implementation of programmable logic controllers (PLCs). These devices control machinery and processes across various sectors. As industries aim for efficiency, PLC engineering becomes crucial.

In manufacturing, PLCs manage everything from assembly lines to robotic systems. They streamline operations and ensure precision. However, dependence on PLCs raises concerns. What if these systems fail? These questions remind us that technology is not infallible.

Moreover, the rapid evolution of PLC technology challenges engineers. They must keep pace with new tools and programming languages. This constant change can feel overwhelming. Despite these challenges, the role of PLC engineering remains vital. It drives innovation and shapes the future of industry.

PLC Engineering, or Programmable Logic Controller engineering, is a crucial field in modern automation. These controllers are designed to facilitate the automatic control of machinery and industrial processes. They provide a digital means to manage operations, which improves efficiency and accuracy in various sectors. PLCs are widely used in manufacturing, robotics, and even in complex transportation systems.

The definition of PLC Engineering encompasses both hardware and software aspects. On the hardware side, it includes the physical devices used for control. Software involves programming languages tailored for PLC systems. Engineers often face challenges such as debugging and ensuring compatibility across different systems. Each project brings unique requirements, leading to varying solutions. It’s not always straightforward. Mistakes in programming can lead to unintended outcomes, which require careful analysis and adjustment.

Furthermore, PLC Engineering affects the workforce significantly. As automation increases, the demand for skilled engineers rises. However, there is a skills gap that needs to be addressed. Training programs must evolve to keep pace with technological advances. Engineers must adapt to rapid changes and revisit their knowledge regularly. This dynamic environment offers opportunities, yet it demands continuous learning and reflection.

| Dimension | Description | Impact on Industry |

|---|---|---|

| Automation | The use of control systems for operating equipment. | Increased efficiency and reduced manual labor costs. |

| Flexibility | Ability to adapt to changing production processes. | Enhanced capability to meet diverse market demands. |

| Real-time Monitoring | Continuous tracking of equipment and processes. | Improved maintenance and reduced downtime. |

| Integration | Combining various control systems into one interface. | Streamlined operations and better resource management. |

| Data Collection | Gathering operational data for analysis and decision making. | Enhanced decision-making based on real data insights. |

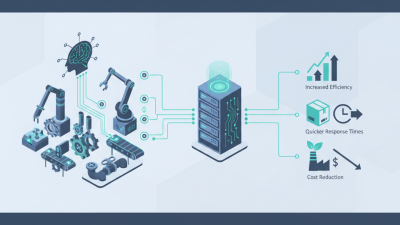

Programmable Logic Controllers (PLCs) are crucial to modern industrial automation. These devices control machinery and processes efficiently. They replace traditional relay-based systems. PLCs increase flexibility and reduce downtime. This is vital for industries seeking competitive advantages.

In industrial automation, PLCs monitor inputs from sensors. They execute logic operations and send commands to actuators. This quick decision-making enhances productivity. For instance, a PLC can manage a conveyor belt system. It ensures products are sorted and directed accurately. However, integration challenges may arise with legacy systems.

Moreover, PLCs contribute to data collection. They gather performance metrics and operational data. This information helps in optimizing processes. Yet, relying heavily on PLCs can lead to potential vulnerabilities. If a PLC fails, the entire system may halt. Industries must prepare for such scenarios. Maintenance and upgrade strategies should be in place. Incorporating redundancy is also essential for disaster recovery.

PLC engineering plays a significant role in enhancing manufacturing efficiency and productivity. The integration of Programmable Logic Controllers (PLCs) in industrial processes leads to streamlined operations. According to a report by the International Society of Automation, companies that adopt PLC technology often see productivity increases of up to 30%. This notable improvement is essential in a competitive market.

However, not all implementations are flawless. Some organizations encounter challenges such as integration issues with existing systems. A study from the Automation Federation indicates that nearly 40% of companies experience delays during PLC system integration. This can lead to lost production time. While PLCs promise increased efficiency, companies must approach their implementation thoughtfully.

Data from McKinsey reflects that automation, including PLC usage, has the potential to boost labor productivity by 25% across various sectors. Yet, companies must invest in staff training. A lack of skilled personnel can negate the benefits of automation. Addressing these issues is crucial for maximizing the potential of PLC engineering in modern manufacturing.

PLC technology has transformed various industries, enhancing operational excellence and efficiency. Manufacturing is a key sector where Programmable Logic Controllers (PLCs) are widely adopted. According to a report by MarketsandMarkets, the global PLC market is projected to reach $14.6 billion by 2025. This growth is driven by the need for automation and real-time data processing in production lines.

In the automotive industry, PLCs play a vital role in assembly lines. These systems ensure precision and speed, reducing production time significantly. For instance, a single automotive plant can implement hundreds of PLCs to control robots and machinery. However, challenges arise in integrating new PLC systems with outdated machinery. This integration often requires careful planning and skilled personnel.

Tips: Regular training for staff is essential. Keeping your team updated on PLC technology can minimize downtime during transitions. Additionally, consider investing in scalable systems that can grow with your production needs.

The food and beverage industry also benefits from PLCs. They enhance processes like bottling, packaging, and quality assurance. According to the Food Processing Technology report, automation in this sector can improve productivity by over 30%. Nonetheless, the reliance on automation can lead to vulnerabilities. Cybersecurity concerns are prevalent as networks become more interconnected. Investing in robust security measures should be a priority.

In today's rapidly evolving industrial landscape, PLC (Programmable Logic Controller) engineering plays a crucial role. As industries integrate automation, PLC systems manage complex processes efficiently. These systems allow machines to communicate, enhancing operational workflow. However, challenges arise in interoperability and scalability, as older PLC versions may struggle with new technology.

Future trends indicate a significant shift toward Industry 4.0 integration. This movement incorporates IoT (Internet of Things) devices, enabling real-time data collection and analysis. The synergy between PLCs and IoT makes processes smarter. For example, manufacturers can predict maintenance needs, reducing downtime. Yet, this integration is not without issues. Security risks increase as more devices connect to networks.

Moreover, the workforce must adapt. Workers need skills in both PLC engineering and digital technologies. This presents a learning curve, creating potential gaps in expertise. Employers must invest in training programs to cultivate these skills, ensuring their teams can navigate this complex landscape. Effective implementation of PLC engineering is essential, yet it requires thoughtful reflection on potential obstacles.