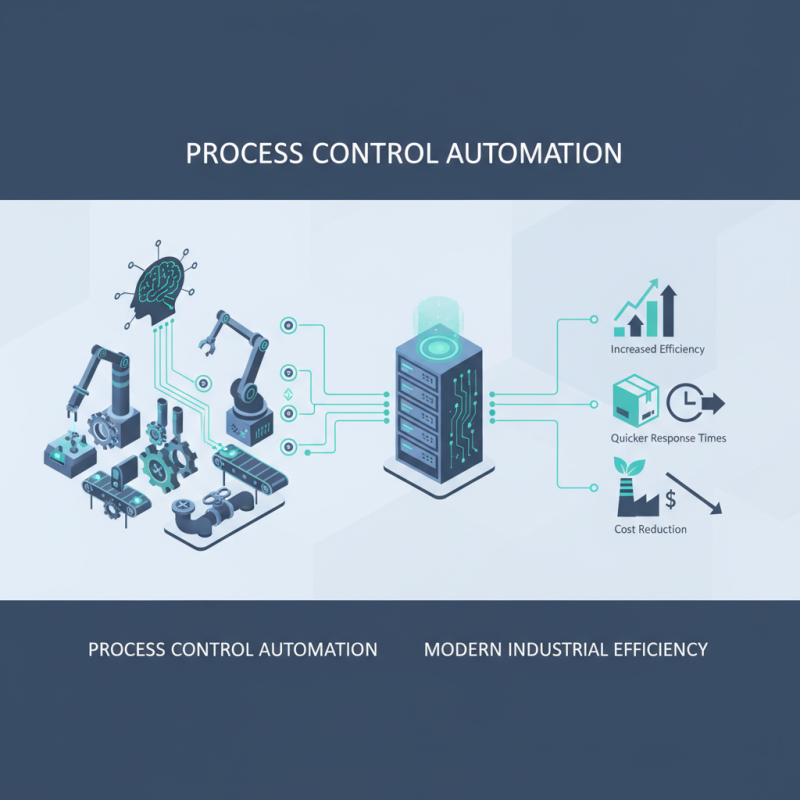

In the rapidly evolving landscape of modern industry, the efficiency and reliability of production processes have become pivotal to maintaining a competitive edge. One of the most significant advancements has been the advent of process control automation. This technology enables industries to streamline operations, reduce human error, and enhance overall productivity by integrating sophisticated control systems that monitor and optimize various processes in real-time. The implementation of process control automation not only ensures consistency in product quality but also facilitates quicker response times to changing production demands.

As industries face increasing pressure to improve operational efficiency and sustainability, process control automation emerges as a crucial tool. Its ability to gather and analyze vast amounts of data allows for better decision-making and proactive adjustments to manufacturing processes. This transformative approach not only reduces costs by minimizing waste and downtime but also helps companies to comply with stringent regulatory standards. In summary, process control automation is not just a technological upgrade; it represents a fundamental shift in how industries operate, underpinning the quest for enhanced efficiency and greater responsiveness in a complex global market.

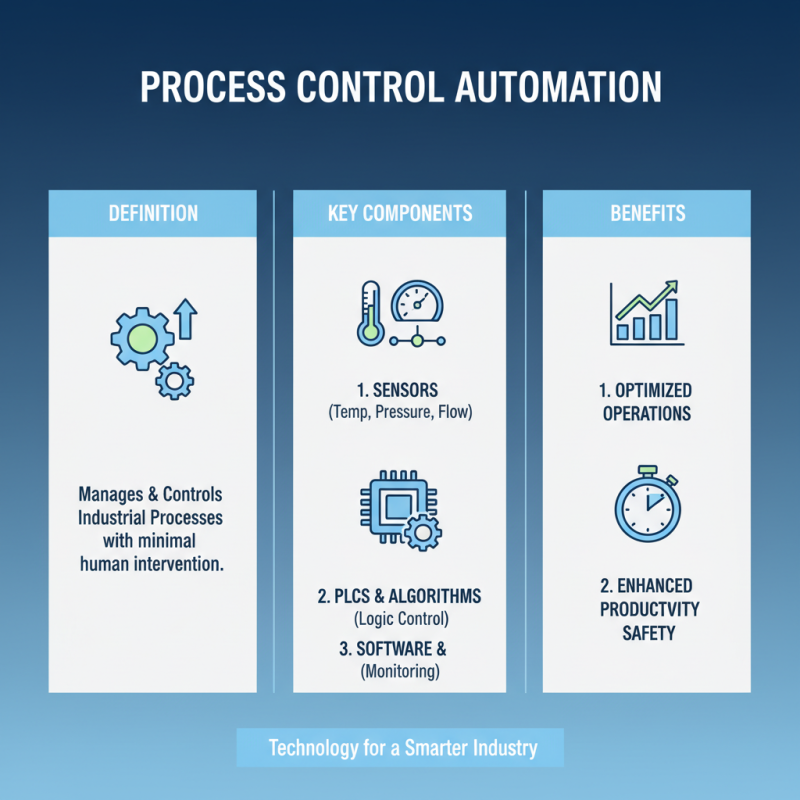

Process control automation refers to the use of technology and systems to manage and control various industrial processes with minimal human intervention. This practice involves integrating hardware and software solutions to monitor parameters such as temperature, pressure, flow, and chemical composition, ensuring optimal operating conditions. By employing programmable logic controllers (PLCs), sensors, and advanced control algorithms, industries can streamline their operations, enhance productivity, and improve overall safety.

The significance of process control automation in industry cannot be overstated, particularly in an era where efficiency and precision are paramount. Automated systems enable real-time data collection and analysis, allowing for quick adjustments in response to changing conditions. This not only reduces the likelihood of human error but also minimizes waste and energy consumption. Moreover, automated processes can be designed for scalability and adaptability, making it easier for manufacturers to respond to market demands and innovate their product lines. Overall, process control automation represents a critical component in the quest for modern industrial efficiency.

Process control automation systems are integral to enhancing efficiency in modern industrial operations. These systems utilize a variety of key components to streamline processes, minimize errors, and boost productivity. One of the foundational elements is sensors, which play a crucial role in monitoring variables such as temperature, pressure, and flow rates. By constantly collecting data, sensors enable real-time adjustments to maintain optimal operating conditions, ensuring consistent product quality.

Another vital component is the programmable logic controller (PLC), which acts as the brain of the automation system. PLCs interpret data from sensors and execute control commands to machinery and system operations. This automated decision-making reduces the need for human intervention, thereby decreasing response times and improving safety. Additionally, human-machine interfaces (HMIs) are essential for operators to monitor system performance and interact with automation components effectively. HMIs provide visual representations of processes, allowing quick assessments and streamlined control over operations.

Together, these components create a cohesive process control automation system that is fundamental to achieving high levels of industrial efficiency.

The implementation of process control automation has become a cornerstone of efficiency in modern industrial operations. Utilizing advanced technologies, such as machine learning and data analytics, companies can achieve significant improvements in their production processes. According to a report by McKinsey, organizations that adopt automation practices can increase their operational efficiency by up to 20-30%, as it allows for real-time monitoring and adjustments throughout the production cycle. This streamlined approach minimizes downtime and reduces waste, leading to substantial cost savings.

Moreover, the integration of automation technologies enhances quality control and consistency in production. For instance, a study by the International Society of Automation indicates that automated control systems can reduce variability in product quality by up to 50%, thereby ensuring that products meet the highest industry standards. Additionally, thanks to enhanced data collection and analysis capabilities, businesses can identify and remedy inefficiencies quickly, enabling continuous improvement. As industries strive for greater competitiveness, the strategic adoption of process control automation is not just beneficial—it is essential for maintaining leading positions in today’s fast-paced market environment.

Process control automation is a critical driver of modern industrial efficiency, yet it faces numerous challenges that organizations must address. One significant challenge is the integration of legacy systems with new automated technologies. According to a report by the International Society of Automation, over 60% of manufacturing plants still rely on outdated equipment, which can lead to inefficiencies and increased downtime. Transitioning to fully automated systems requires not only substantial financial investment but also a skilled workforce capable of managing sophisticated technologies.

To overcome these challenges, businesses should focus on incremental upgrades and training programs for employees. Implementing modular solutions allows companies to gradually integrate automation without extensive disruptions. A report from McKinsey highlights that organizations that prioritize ongoing training see a 25% increase in productivity within the first year of automation implementation. Additionally, fostering a culture of continuous improvement encourages employees to adapt to new technologies quickly.

Tips: Start with small-scale automation projects to test the waters before full implementation. This approach minimizes risk and provides valuable insights into the benefits and challenges of process control automation in your specific industrial setting. Moreover, engage employees early in the automation journey to ensure their buy-in and equip them with the necessary skills for the future of work.

As industries continue to evolve, the future of process control automation lies in the integration of advanced technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT). These innovations are enabling businesses to streamline operations, enhance decision-making, and optimize resource usage, driving unprecedented efficiency levels. With real-time data analytics and predictive maintenance capabilities, organizations can foresee potential disruptions and address them proactively, ensuring continuous production without costly downtimes.

Tips: Embracing AI can transform data analysis from arduous tasks into automated processes, allowing staff to focus on strategic initiatives. Regularly train your teams on new technologies to maximize their effectiveness and adaptability in an automated environment.

Moreover, the shift towards decentralized systems represents a significant trend in process control automation. By leveraging cloud computing and edge processing, industries can achieve greater flexibility and resilience in their operations. This decentralized approach not only facilitates quicker response times but also enhances collaboration across different sites and departments, resulting in a more synchronized operational landscape.

Tips: To effectively implement decentralized automation, establish clear communication channels and protocols among teams. Regularly assess and update your processes to align with technological advancements and operational needs.

| Dimension | Description | Current Value | Future Trend (2025) |

|---|---|---|---|

| Energy Efficiency | Reduction in energy consumption through optimized control | 15% reduction achieved | 20% target reduction |

| Product Quality | Consistency and reliability in product outputs | 98% quality compliance | 99.5% target compliance |

| Maintenance Costs | Expenses related to routine and unplanned maintenance | $500,000 annually | $350,000 projected |

| Throughput | Volume of production over a specified period | 1,000 units/day | 1,500 units/day target |

| Downtime | Total time production is halted | 12 hours/week | 6 hours/week target |